Product origin:

ChinaShipping port:

Any port in ChinaLead Time:

Prompt delivery|

Product Information |

|

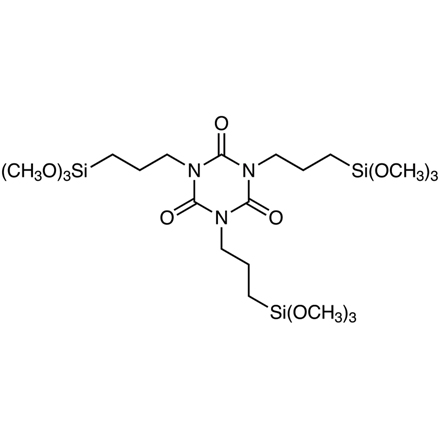

Product name |

Tris[3-(trimethoxysilyl)propyl] Isocyanurate |

|

CAS No. |

26115-70-8 |

|

Molecular Weight |

615.851 |

|

Molecular Formula |

C21H45N3O12Si3 |

|

Technical Parameter |

Quality Indicators:

| Item | Indicator |

| Appearance | Transparent liquid |

| Density (25°C) | 1.170 |

| Viscosity | 95 cSt |

| Flash Point, Pensky-Martens Closed Cup (ASTM D93) | 102°C |

| Boiling Point (760 mmHg) | >150°C |

|

Usage |

Functions and Applications:

(1) Excellent Adhesion Performance

For traditionally hard-to-bond substrates such as plastics, glass, aluminum and steel, it can significantly improve the bonding strength and maintain a stable bonding effect even after harsh environments such as damp heat aging.

(2) Superior Thermal Stability

It can maintain thermal stability at 200°C, adapting to the high-temperature processing of hot melt adhesives (such as melting and coating) and the continuous high-temperature working conditions that end products may face. It solves the problem of bonding failure caused by the easy decomposition and volatilization of conventional silanes at high temperatures.

(3) Low Volatility and High Boiling Point

Its high boiling point characteristic of 230°C (0.05mmHg) results in low volatilization loss in high-temperature application scenarios of hot melt adhesives, enabling it to fully exert the adhesion promotion effect and avoid the decline of bonding performance caused by silane loss.

(4) Wide Resin Compatibility

It has good compatibility with most hot melt adhesive resins (such as EVA, polyamide, polyester, etc.) and sealant matrix resins such as SPUR+ prepolymers. It can be added without substantial formula adjustment, reducing the application threshold.

(5) Minimal Impact on Elastomer Properties

The design of low alkalinity and dispersed alkoxy structure ensures that its addition in sealant formulations will not significantly affect the elastomer characteristics of the product (such as high elongation and low modulus), balancing adhesion and flexibility.

| Structural Characteristics | Corresponding System Advantages |

|---|---|

| High Concentration of Trimethoxysilyl Groups | Provides effective adhesion to various substrates such as plastics, glass, aluminum and steel, forming a stable interfacial bonding. |

| Isocyanurate Chemical Structure |

|

Recommended Dosage by HMA Type: 1.00% for EVA hot melt adhesives; 1.00%~1.50% for polyamide hot melt adhesives; for polyester hot melt adhesives, it needs to be adjusted according to specific formulations, and testing in the range of 0.50%~1.50% is recommended;

Core Principle: Formula optimization shall be carried out for the specific hot melt adhesive system used to ensure that the bonding performance matches the original processing properties of the hot melt adhesive (such as viscosity and curing speed).

JN590 exhibits outstanding performance in SPUR+ prepolymer sealants and high-temperature hot melt adhesive applications by virtue of its core advantages of "high bonding efficiency + heat resistance stability + low volatility + wide resin compatibility". Its unique combination of isocyanurate structure and high concentration of trimethoxysilyl groups

not only solves the bonding problem of hard-to-bond substrates (plastics, metals, glass), but also maintains the flexibility and mechanical stability of the product, making it particularly suitable for high-end application scenarios with comprehensive requirements for bonding strength, heat resistance and flexibility.

Quality Indicators:

| Item | Indicator |

| Appearance | Transparent Liquid |

| Density (25°C) | 1.170 |

| Viscosity | 95 cSt |

| Flash Point, Pensky-Martens Closed Cup (ASTM D93) | 102°C |

| Boiling Point (760 mmHg) | >150°C |

| HMA Type | JN590 Dosage | Tensile Strength psi (MPa) | 100% Modulus psi (MPa) | Elongation % | Tear Strength lb/in (N/mm) |

|---|---|---|---|---|---|

| EVA Hot Melt Adhesive | 0% | 469 (3.23) | 468 (3.23) | 96 | 198 (34.7) |

| 0.50% | 435 (3.00) | 434 (3.00) | 93 | 168 (24.4) | |

| 1.00% | 597 (4.12) | 591 (4.07) | 88 | 204 (35.7) | |

| 1.50% | 476 (3.28) | 476 (3.28) | 95 | 184 (32.2) | |

| Polyamide Hot Melt Adhesive | 0% | 473 (3.26) | 380 (2.62) | 56 | 240 (42.0) |

| 0.50% | 434 (3.00) | 434 (3.00) | 45 | 210 (36.8) | |

| 1.00% | 705 (4.86) | - | 62 | 263 (46.1) | |

| 1.50% | 679 (4.68) | 753 (5.19) | 60 | 269 (47.1) |

Packaging and Storage: Packed in 25kg plastic drums, 190kg standard steel drums and IBC ton drums. Store indoors in a dark, ventilated, cool and dry place. Ensure the drum lids are well sealed to effectively isolate air. Moisture in the air will react with it, leading to hydrolysis, polymerization and deterioration.